Made in the USA

|

|

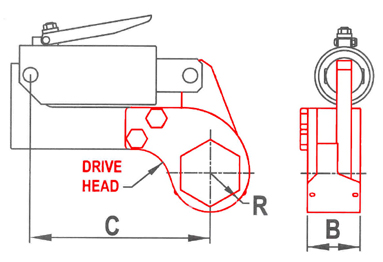

Model Si torque wrenches use a quick-change Drive Head with a double-ended socket to help you torque industrial size bolts on heavy equipment. Each low profile, offset Drive Head* is designed with the smallest possible head radius to fit any size API or ANSI flange or other big bolt application. Torque reaction is in the plane of the hex nut or bolt, thereby eliminating the tendency of the wrench to twist off the nut when torque is applied. Operation is simple! One worker positions the wrench on a bolt head and pushes the control valve on the torque wrench. The cylinder rod strokes out and turns the fastener 15 degrees. Separate electrical control pendants are not used. When the control valve is released, the load is removed and the wrench mechanism ratchets. Another stroke can be removed. The Model Si torque wrench will NEVER "hydraulically lock" onto a nut or bolt. To loosen bolts, the tool is simply turned over. From the model Si-1.5 on up to the Model Si-150, you get BMF quality and engineering built-in. Torque output is accurate within 3%. BMF Torque

Wrench are stronger. BMF Torque

Wrenches are safer. BMF Torque

Wrenches are more reliable. All of these features combine to give you a hydraulic powered torque wrench that can be safely, reliably, and quickly torque industrial size bolts. Model Si Torque Wrenches are available with any size or shape socket, in inch or metric sizes, from 1" to 9-1/8" (25mm to 232mm). *Each Drive Head is a complete ratcheting box wrench and is easily

changed out. Individual sockets are also available.

|

|

|

WRENCH

MODEL |

MAX TORQUE

(Ft-Lbs) |

MAX TORQUE

(N-m) |

BOLT DIAMETER

RANGE |

HEX SOCKET

SIZE RANGE |

C

LENGTH |

APPROXIMATE

WEIGHT (Lbs) |

| Si-1.5 | 1500 | (2000) | 3/4" to 1-1/4" | 1" to 2" | 7.50 | 7 to 11 |

| Si-4.5 | 4500 | (6100) | 1" to 1-3/4" | 1-1/2" to 2-3/4" | 9.00 | 11 to 20 |

| Si-8 | 8000 | (10800) | 1-1/4" to 2-1/4" | 1-7/8" to 3-1/2" | 11.50 | 16 to 28 |

| Si-16 | 16,000 | (21700) | 1-5/8" to 2-3/4" | 2-1/2" to 4-1/4" | 14.00 | 26 to 38 |

Model Si Torque Wrenches fit directly onto nuts and bolts and apply torque in the plane of the bolt head. This design eliminates the tendency to twist the wrench off bolt heads when torque is applied. By removing two bolts and a clevis pin the operator can quickly and easily change the Drive Heads.

In addition to the standard line of Model Si Torque Wrenches listed here, BMF Torque Wrench Co. offers custom designs which can torque bolts in pockets and other areas which are difficult to access. Call us today for a free consultation and quote.

Also available are 12-point hex drives, octagon drives, spline drives and square drive adapters to fit standard power sockets.

Choose a Model Si Torque Wrench when you want to safely, quickly, and reliably torque large nuts and bolts.

For data on individual Drive Heads visit our Drive Head page.